The Challenge

Kayaks can provide access to waters where no other boat can venture. Waters that provide a remote, quiet, and pure fishing experience. However, kayaks have become too heavy for most people to move effectively. An overabundance of gear is being loaded on these heavy kayaks and the end result is a small boat. Most kayak fishing anglers today are limited to boat ramps due to the challenge of the weight of their boats and the quantity of gear being used. Over the years, Eric Jackson has been using his kayaks primarily to get to remote protected waters. The more remote, the better. He believed it was time to make a fishing kayak that was ultra-lightweight and required very little water to float. Perhaps there was a way to get to his favorite haunts easier, or find even more remote areas to fish.

It started with an idea.

Eric raced in the 1992 Olympics in Barcelona in a 15-pound carbon fiber kayak. He averaged as many as 500 training sessions per year in these kayaks over a 15-year period. Perhaps it was time to make a high-performance fishing kayak from advanced composites? Nobody had done that yet, and the industry trend was going for bigger, heavier, and cheaper. The thought of having a lightweight, simple, high-performance fishing kayak was so exciting that Eric chose to start a company from scratch to make it a reality.

Adversity

Eric started with few resources other than a credit line offered by his local bank, Security Federal. He had to build a team of experts to design, prototype, and ultimately manufacture these cutting edge kayaks. Nothing about the Apex Tyr would be a copy of anything done before. New, innovative, and better in every way was the mandate. COVID-19 hit right in the middle of the R+D process. With R+D staff being spread around the country having little ability to travel, delays and obstacles were the norm. The team, known as the “Apex Party” would not be deterred, however. Where there is a will, there is a way.

Limitless

The typical obstacles that get in the way of kayak manufacturers, Eric decided, would not exist with Apex. “Cost” being the first one. Yes, there are cheaper materials, processes, and people in the world. However, the goal is to create the highest performance fishing kayak possible, and that means using the best available materials, manufacturing processes, and people. With this mindset and company mandate, we have created a new design that has started the next big evolution of the fishing kayak.

Determination

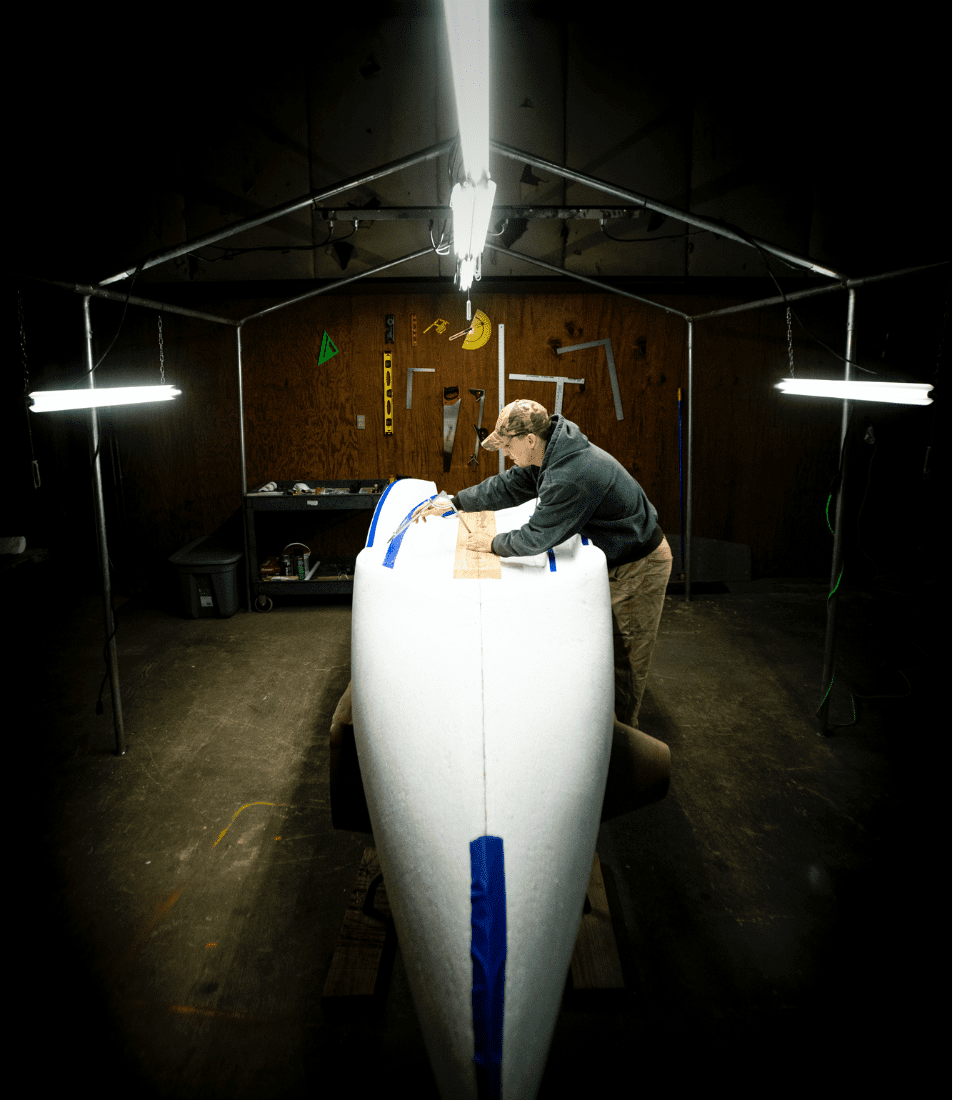

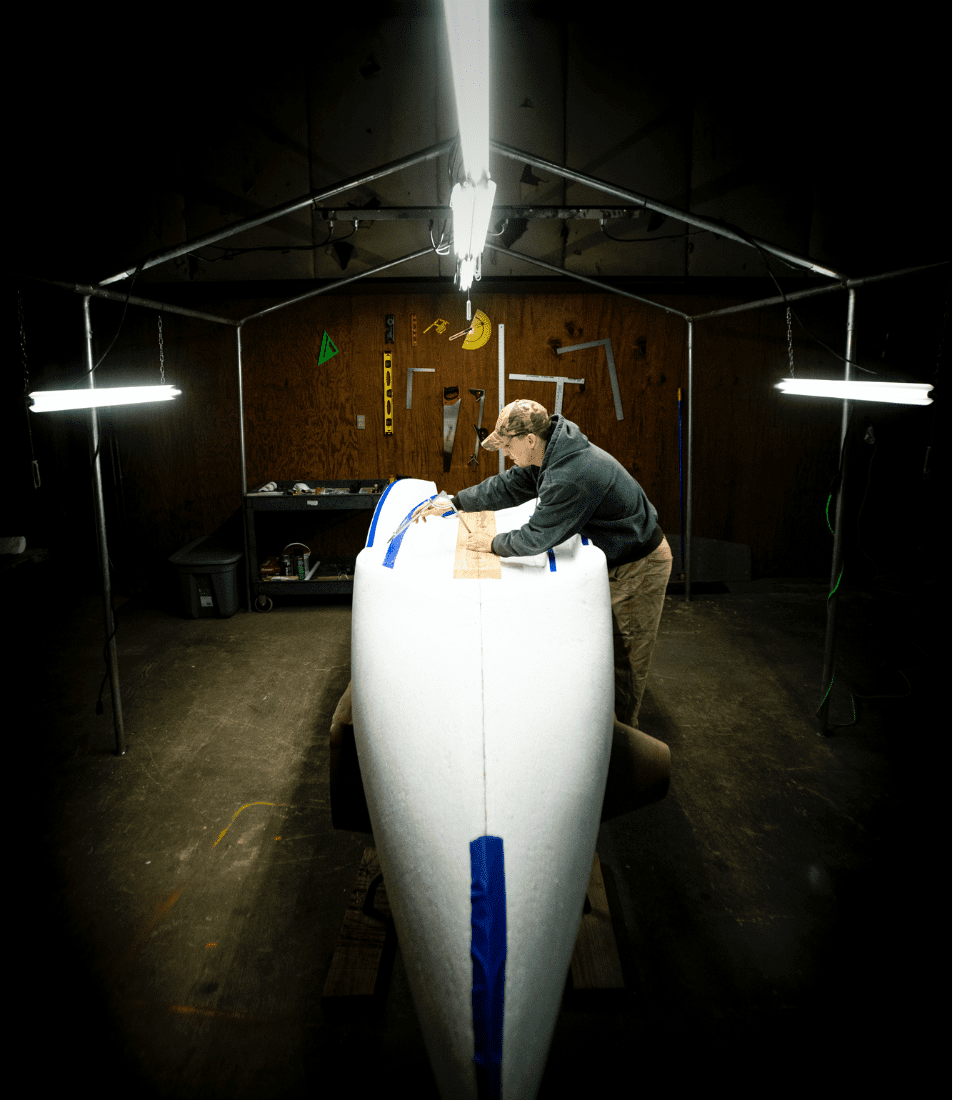

The Apex Party recognized the challenges were great and the bar set high early on. The original plan was to subcontract out the infusion molding process, but it became clear that the need for near perfection was something that would not be internalized by hired help, that Apex would have to have our own people, fishermen, kayakers, make our own boats. This led to finding and setting up a factory, and getting the expertise in-house to mold the world’s most expensive materials into the designs we wanted. It would require research, training, and the guts to take on the project. Eric has 30+ years of experience making plastic boats. This was a different beast. To start an advanced composites manufacturing company was going to take time and determination.

Perseverance

Ultimately when you decide that failure is not an option, and you set your sights at the top, at the Apex. You will find a solution to every challenge and add more challenges as you get going. We found Russ Emanis, who led the Lockheed Martin R+D and manufacturing of the F-22 Rapture fighter jet with carbon fiber, infusion processes. Russ saw the determination and raw energy that was going into overcoming our challenges to manufacture our kayak at the highest standards and joined the Apex Party. This was a turning point for Apex, giving us the right stuff to get the job done.

The Technology

Advanced composites are really a combination of an art form, science, and technology. While the materials and processes we are employing are science, the exact application is both art and experience. Our suppliers work with the military on all levels and have a ton of shared research on materials performance in a variety of scenarios. Carbon fiber shortages 10 years ago have led to new technologies in manufacturing of these precious black fibers and it comes in more configurations than ever before. Advanced design of new fibers along with mixing fibers such as Innegra into the weave is relatively new, but most importantly, this is changing what is possible. With our contacts, relationships, and in house expertise, we are now tied into the most cutting edge processes and materials, positioning us to know and thus create what is coming up that doesn’t yet exist in the market-place. The future is bright with technologies that are being developed, that will make a better kayak, but this has yet to see the light of day in the public eye. Apex will be there, front and center, thanks to our people and position, and we’ll continue to evolve.

What it takes to make

MATERIALS

Carbon fiber isn’t new. Even Innegra isn’t new to the market, but the applications we are using for them most certainly are. Combined with core materials, infusion epoxy and magnets these specific kayak designs have never been experienced in fishing kayaks to date. The head of R+D for Innegra is keeping us on the cutting edge of available materials and we have now been given access to even the prototype materials to boot. Our manufacturing team has to learn how each material works, cuts, lays down, and infuses differently to craft an artwork such as the Apex Watercraft.

PEOPLE

We call our team the Apex Party. Each party member has been hand-picked because of their unique skill-set, knowledge, work ethic, and attitude. We are a group that doesn’t compromise on quality, ever. Each member has their own area of expertise and all are heavyweights in their craft. The bigger the challenge the more excited we get. We experience the true enjoyment of a job well done, and the attention to detail ensures that everything we make is a work of art. We are engineers, artists, designers, kayakers, fishermen and craftsmen.

LOCATION

Rock Island is a special place for Eric Jackson and his family. He founded Jackson Kayak here in 2004 and insisted that Apex Watercraft’s home be in Rock Island as well. Nestled on one side of a 55,000 square foot facility that was formerly a Levi’s Jeans factory, we have 3,000 square feet of space and the ability to grow into as much of the remaining space as needed. Easy access to most of the USA and located in the middle of the Southeast makes hand delivering kayaks possible as the Southeast is a major hub for fishermen, both fresh and saltwater. The low cost of living, and factory space assures that the money spent on making the kayaks can be spent on the best people and materials. Rock Island also offers the best testing grounds imaginable for each Apex design. Whitewater, shallow creeks, deep lakes, and ponds abound. It is a bit of a jaunt to the coast, but for weekend trips, and some bull reds, it is worth it.

Beauty materialiZed.

The Tyr represents our first vision of the evolved fishing kayak realized in carbon fiber form. Function determines the form is our rule, and after careful consideration of the performance we desired, this is what the boat looks like. Simple elegance describes it best. Those who have experienced it agree. The piercing bow is based on the latest boat design technology, also employed in racing SUPs. The high volume bow keeps the boat on the surface and sheds water when piercing waves. The hull is extremely low draft and planing, so very little water is needed to float it. The hull is clean and offers unparalleled stability while moving fast and quietly over the water. It skims, glides, and nearly hovers. The side profile is a smooth double “S” shape that flows neatly for an attractive aesthetic, but the real purpose is to provide a clear space for your hands while paddling, yet providing enough deck volume and sidewall for paddling performance, rod storage and wave protection. The natural Amorim Cork Decking is elegant. It dampens noise, offers traction for standing, and pads your rod and reels. We created the Tyr tackle bag specifically to carry enough gear for the day, but not too much. It is custom-designed, cut and sewn by Marcus Nelson Denim in Knoxville, TN. Pair the bag with the boat and you really have a package to be proud of. It would be difficult to miss the amazing stock paint job on each boat. Multi-staged, clear coat, colors, air brush, pin stripes, and metal flake provide protection to the epoxy and carbon while giving you a piece of art to admire. Our painter has been dressing up some of the world’s most high-end show cars and motorcycles over the years and his skills are legendary. The Stock paint scheme on each Tyr showcases the depth of the carbon, while adding some color, sparkle, and accentuating the shape of the boat. No need to stop there as custom paint jobs are also available to personalize your boat to your specs. Call for a quote.

Light

Sleek

Fast

Practical

Durable

Innovative

Beautiful

Priceless

Your own Apex Watercraft will help make your off-water and on-water experiences magical. Load and unload easily. Drop your Apex tackle bag with only what you need onto the back. Step onto the beautiful deck and push off. Feel the acceleration with each paddle stroke. You are paddling a high-performance machine, a piece of artwork, and the mission of finding fish becomes a joy. Everything you need at your fingertips. You waxed it and it is looking sharp with your custom paint job. It looks amazing on your vehicle, but feels even better on the water. It is worth every penny.