How it all began

Eric Jackson raced his carbon fiber kayak in the 1992 Olympics, won his first World championships in one in 1993 and has built over 100 composite kayaks in his life. While he is proud of the plastic fishing kayaks he has helped develop and sell over the years, he found himself challenged with the weight and awkwardness of the 70-150 pound kayaks, especially when trying to fish remote areas without easy access. He wasn’t the only one. The single biggest complaint his customers and friends had was the excessive weight. Apex Watercraft was born from that simple need, and Eric wanted to take on the challenge of revolutionizing the kayak market for the second time. It was time for a change, for a new species of fishing craft. There was so much more that could improve the fishing experience. Apex was born to do just that, create the best tool for fishing out of a solo, human-powered boat.

Behind the scenes

If there is one thing you can say about Eric, it is that while he is quite capable of doing amazing things by himself, he knows when to develop a team and how to find the best people. Apex was too big and too important a project to attempt to create all of the best practices, designs, manufacturing, and individual components that make up an Apex Watercraft alone. Eric thrives on being around people who are the best at what they do, and they help fuel Eric to be the best at what he does.

Be part of the Evolution

Apex is making history with the lightest weight, most exquisite fishing kayaks ever made. You’ll be awed by the custom paint job, the performance-driven bucket seat design, and the touch and feel when you first run your hands over the swooping curves. Every detail is reimagined to improve the on and off water experience. You can expect a high-performance hull shape that offers unmatched stability and speed, but many of our innovations will come unexpected.

-

Innovate

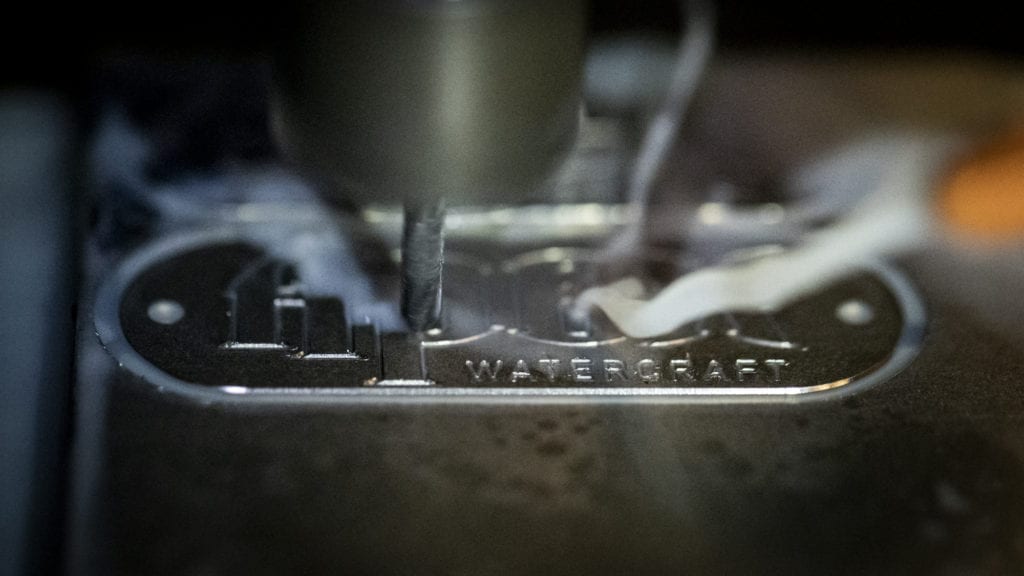

Every curve, every component, every touchpoint is unique. How things were was not considered, but the potential for what could be is the driving factor. A better experience, a craft to be proud of was the mandate.

-

Build

Processes and best practices are only helpful if they are coming from the best-equipped people to deliver on that promise. We are employing the same practices, lead by the same person, who headed the Lockheed Martin manufacturing of the F-22 Rapture, which allowed zero defects in each part.

-

Expand

Our growth is controlled to assure that our best artisans are making each component. As we continue to imagine new horizon lines, we’ll accommodate our thirst to grow, but only if we are creating something unique and worthy of our best efforts.